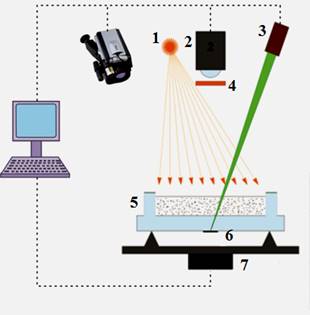

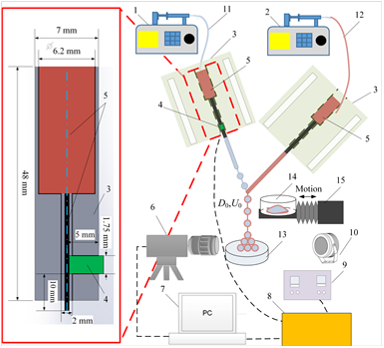

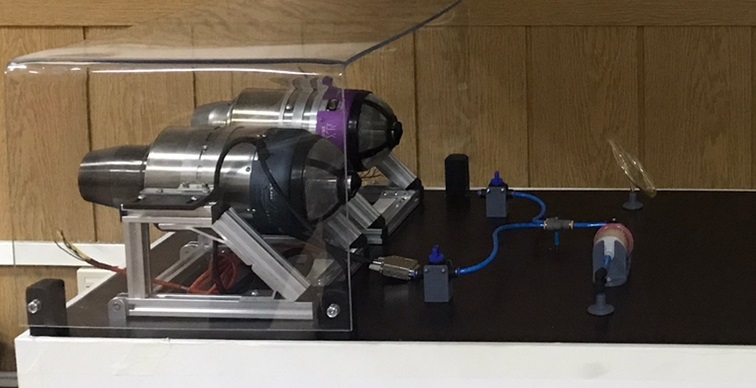

The purpose of the experiments is to study the interaction of the first microgel particle with surfaces, as well as the interaction of the second microgel particle with the first. To form microgel particles, a system for generating a dual flow of liquids has been developed. The resulting flow of microgel particles is formed as a result of the interaction in the air of a microdroplet flow of polymer with a microjet flow of crosslinker.

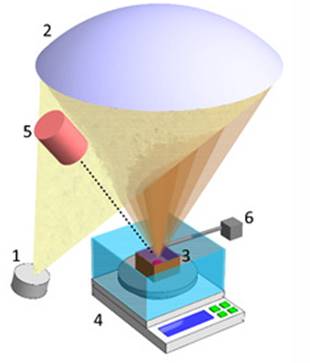

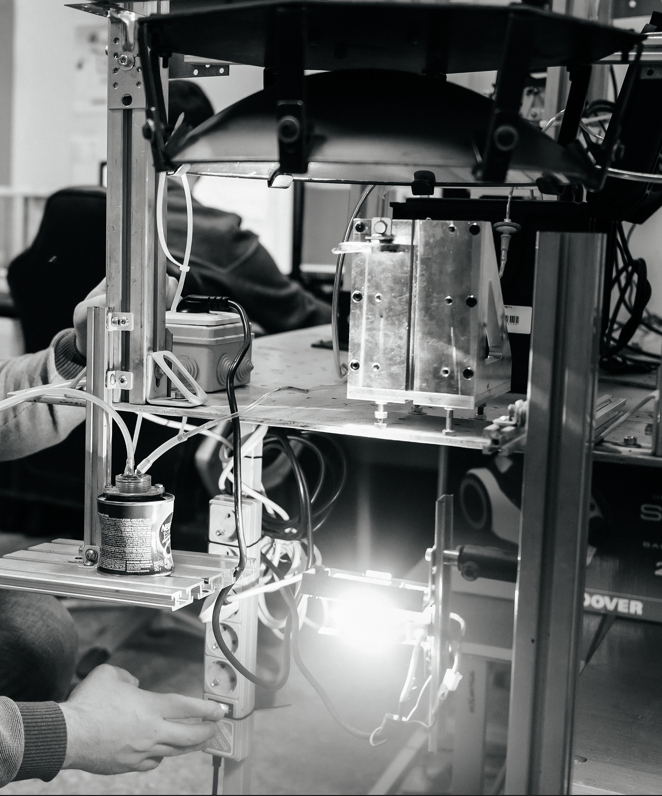

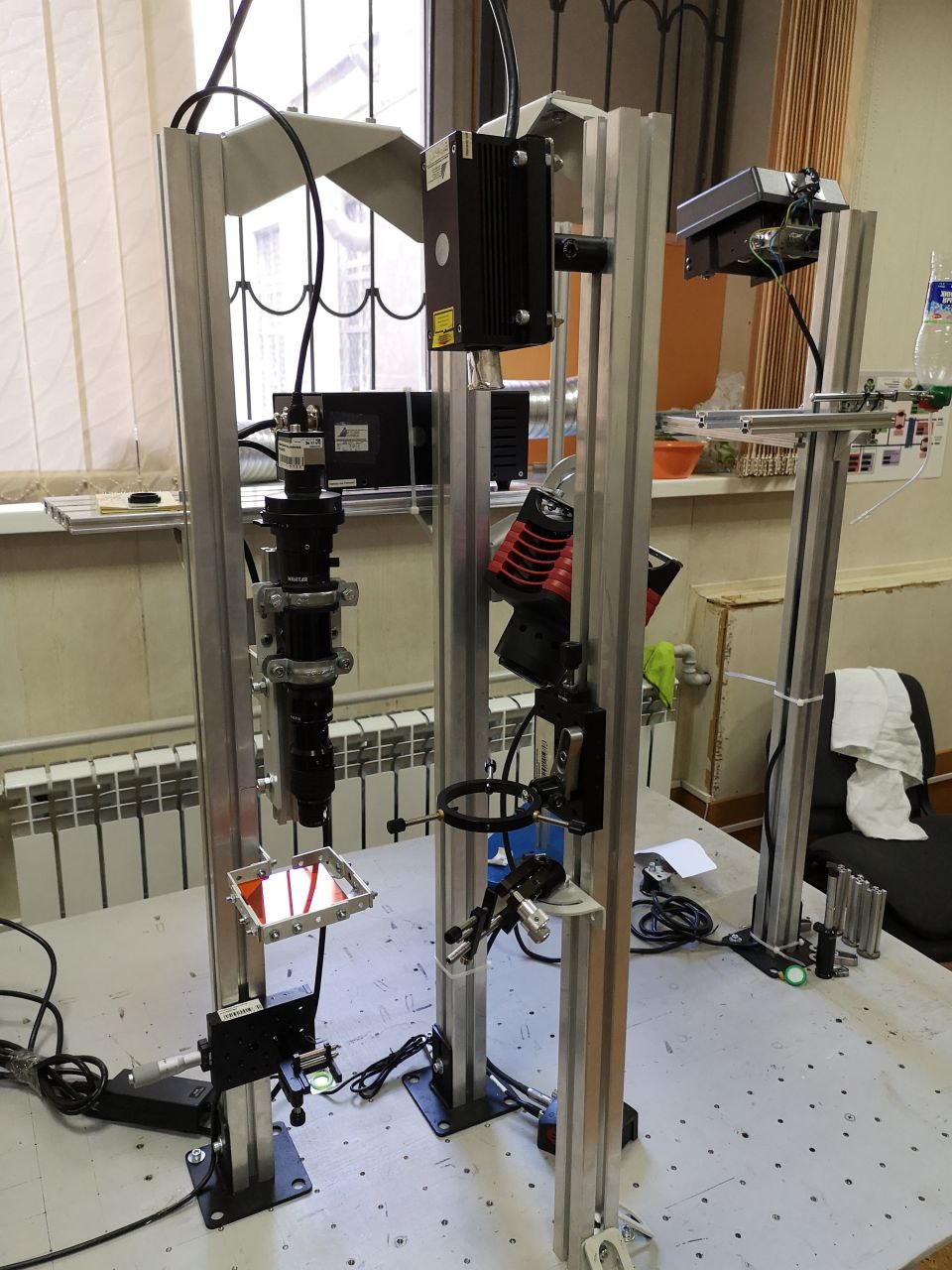

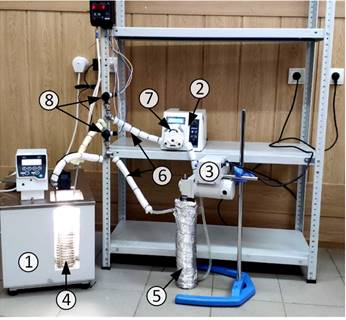

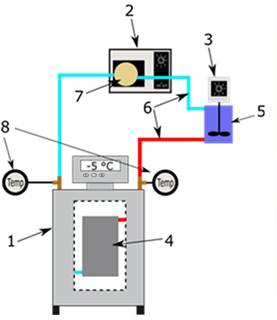

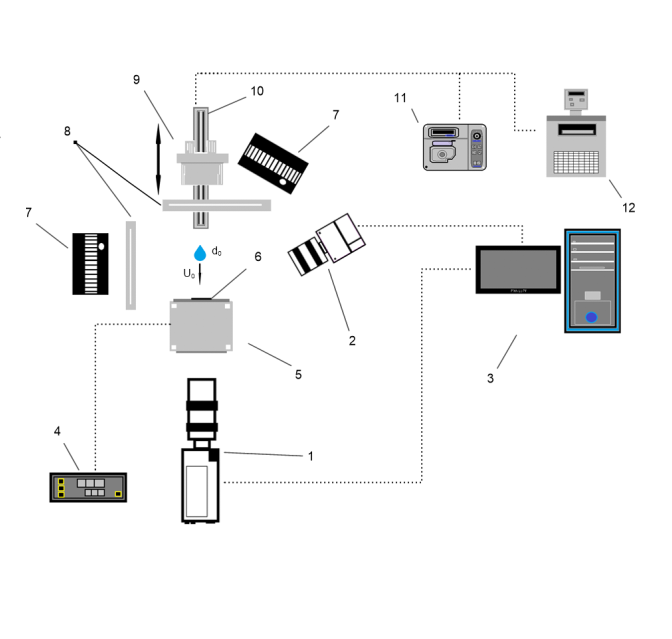

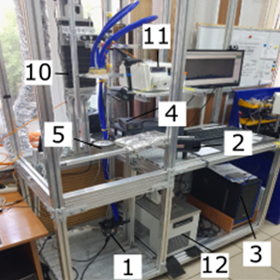

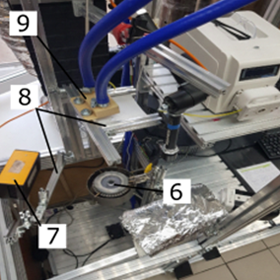

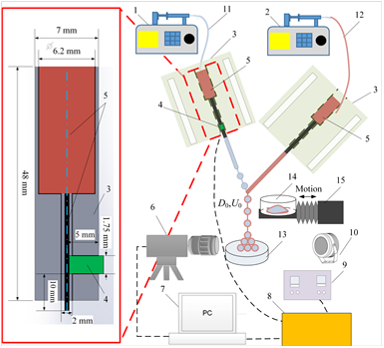

Appearance of the experimental stand: 1 – syringe pump for supplying a polymer solution, 2 – syringe pump for supplying a crosslinker solution, 3 – frame for attaching a needle, 4 – piezo actuator, 5 – syringe needle, 6 – high-speed video camera, 7 – personal computer, 8 – power supply, 9 – signal supply and amplification system, 10 – lighting system, 11 – hose for supplying a polymer solution, 12 – hose for supplying a crosslinker solution, 13 – solid wall; 14 – container for collecting waste liquid; 15 – linear coordinate device

The collision of gel microdroplets with surfaces is recorded using a high-grade Phantom Miro M310 video camera. The high-quality camera is used with a Nikon 200mm FX NIKKOR f/5.6 lens. The main parameters of the processes of interaction of microgel particles with the surface are recorded: Initial diameter of particles D0, speed of movement of microparticles U0, diameter of liquid bridges δ, m; diameter of spreading (deformation) of particles D, m, h – height of the spreading (deformable) particle. The test compounds are supplied using SPLab 02 syringe pumps. The flow speed varies in the range of 0.1–2 m/s due to changes in the pump flow rate.

The crushing of the sodium alginate solution flow is carried out using a multilayer piezoelectric actuator.

Responsible officer: Хомутов Никита Андреевич